Views: 0 Author: Site Editor Publish Time: 2025-07-16 Origin: Site

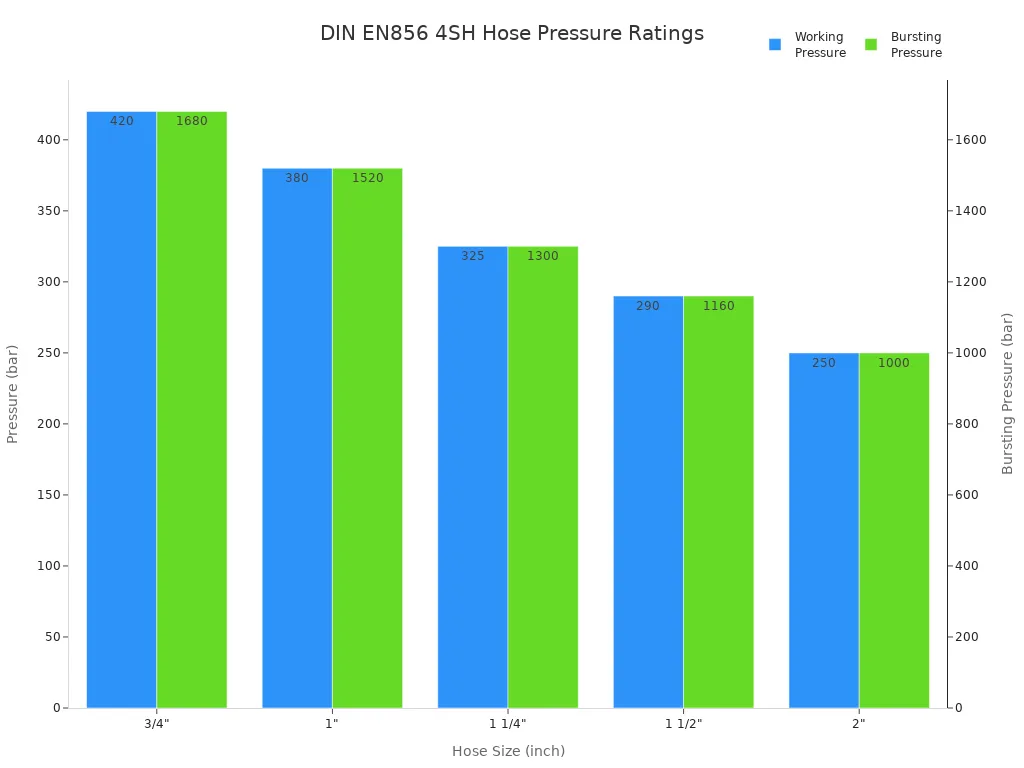

Selecting the right hydraulic hose is very important in factories. Safety and how well things work are the main goals. The biggest difference between 4sp and 4sh hose is how they are made and how much pressure they can take. 4sp hoses, like the din en856 4sp hydraulic hose, are used in many fields. These fields include farming, building, and making products. 4sh hoses can handle more pressure than 4sp hoses. They are good for tough places, like mines and big machines. The chart below shows how 4sh hose pressure ratings help with hard jobs:

4SP hoses have four spiral steel wire layers. They are flexible and can handle medium to high pressure. This makes them good for building, farming, and many factory jobs.

4SH hoses have four to six thicker steel wire layers. They can handle very high pressure and tough jobs. These hoses work well in mining and with big machines.

Both hoses resist oil, weather, and wearing out. 4SP hoses bend more easily. 4SH hoses last longer in hard jobs and high pressure.

Always check the hose’s pressure, temperature, and fluid type. Make sure it fits your system to stay safe and work well.

Follow the maker’s rules and check hoses often. This stops problems, saves money, and keeps machines working well.

The din en856 4sp hydraulic hose is very strong. It has a tough inside layer made from synthetic rubber. This layer stops oil and scratches from causing damage. Four steel wire layers make the hose strong and bendy. The outside cover is also synthetic rubber. It keeps out bad weather, oil, and scratches. Grandflex 4sp hoses follow strict rules like EN 856 4SP and DIN 20023 4SP. These hoses work in very hot or cold places, from -40°C to +125°C. The hose lasts a long time, even in rough places.

Oil-resistant synthetic rubber inner tube

Four spiral steel wire reinforcement layers

Abrasion- and weather-resistant synthetic rubber cover

Shore hardness of 85A for durability

Steel wire strength rated at 3250N

Certified to ISO9001:2015, MSHA, and GOST

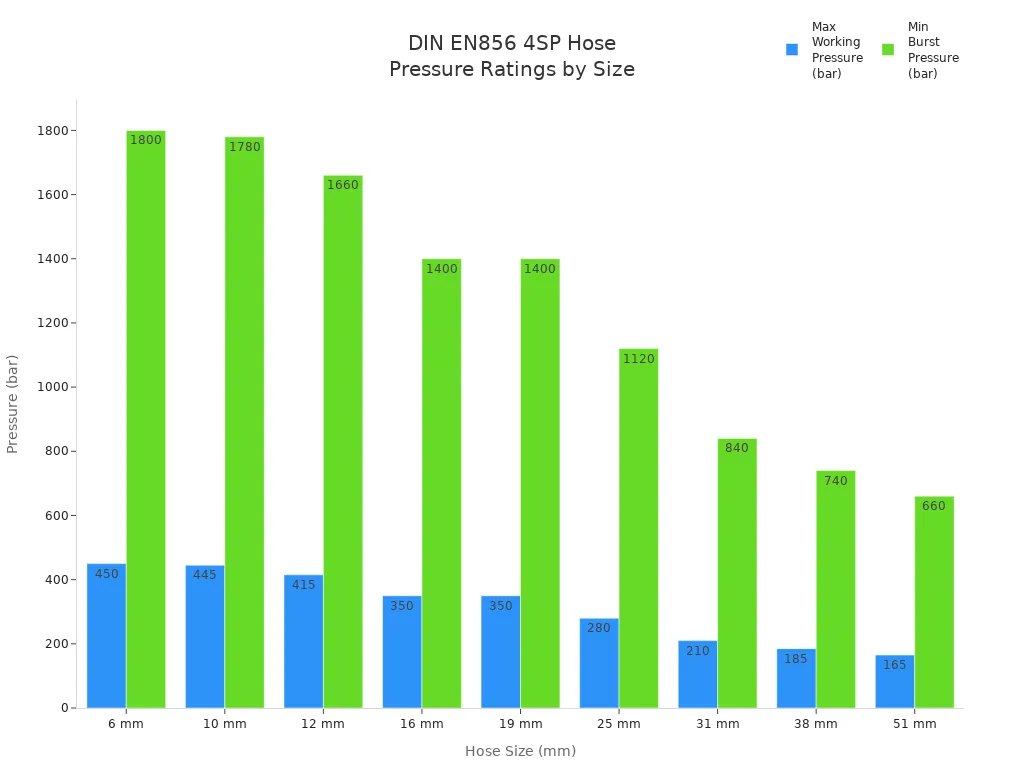

4sp hoses work well in high pressure systems. The din en856 4sp hydraulic hose can handle up to 450 bar (6527 psi) for small hoses. It can burst at 1800 bar (26106 psi). The pressure changes with hose size. This keeps people safe and fits many jobs. The hose stays strong and bendy in hot or cold. Grandflex 4sp hoses meet all EN 856 4SP rules.

| Hose Size (mm) | Max Working Pressure (bar) | Max Working Pressure (psi) | Min Burst Pressure (bar) | Min Burst Pressure (psi) | Continuous Service Temp (°C) | Max Operating Temp (°C) |

|---|---|---|---|---|---|---|

| 6 | 450 | 6527 | 1800 | 26106 | -40 to +100 | 125 |

| 10 | 445 | 6454 | 1780 | 25816 | -40 to +100 | 125 |

| 12 | 415 | 6019 | 1660 | 24076 | -40 to +100 | 125 |

| 16 | 350 | 5076 | 1400 | 20305 | -40 to +100 | 125 |

| 19 | 350 | 5076 | 1400 | 20305 | -40 to +100 | 125 |

| 25 | 280 | 4061 | 1120 | 16244 | -40 to +100 | 125 |

| 31 | 210 | 3045 | 840 | 12183 | -40 to +100 | 125 |

| 38 | 185 | 2683 | 740 | 10733 | -40 to +100 | 125 |

| 51 | 165 | 2393 | 660 | 9572 | -40 to +100 | 125 |

4sp hoses are used in places with high pressure. People use them in mining, oilfield machines, and building equipment. These hoses can take a lot of pressure and fast changes. This makes them good for hard jobs. The din en856 4sp hydraulic hose works with many fluids. It is strong and bendy, so it fits many systems. The hose is safe to use from -40°C to +125°C. Grandflex 4sp hoses help factories work well and last a long time.

Note: 4sp hoses are great at handling fast pressure changes and stopping wear, so they are trusted for important hydraulic systems.

4sh hoses use a strong hydraulic hose structure. The inner tube consists of black synthetic rubber. This material resists abrasion, corrosion, and oil. Four layers of high-tensile, spiraled steel wire reinforce the hose. These layers give 4sh hoses their strength and allow them to handle high pressure. The outer cover uses high-quality synthetic rubber. This cover protects against weather, ozone, cuts, oil, and aging. The temperature range for 4sh hoses goes from -40°C (-104°F) to +100°C (+212°F). This wide range makes them suitable for many industrial settings. The design of 4sh hose ensures long service life in tough environments.

Note: The hydraulic hose structure of 4sh hoses helps them perform well in heavy-duty hydraulic systems.

4sh hoses meet EN 856 4SH standards. They support high-pressure applications with maximum working pressures up to 6,090 psi for the 3/4" size. Burst pressures can reach 16,800 psi. 4sh hose comes in sizes from 3/4" to 2" (19mm to 51mm inner diameter). The pressure ratings for each size are as follows:

| Size (inches) | Max Working Pressure (MPa/psi) | Burst Pressure (psi) |

|---|---|---|

| 3/4" (19mm) | 42.0 MPa / 6,090 psi | 16,800 |

| 1" (25mm) | 38.0 MPa / 5,510 psi | 15,200 |

| 1-1/4" (31.5mm) | 32.5 MPa / 4,713 psi | 13,050 |

| 1-1/2" (38mm) | 29.0 MPa / 4,205 psi | 11,600 |

| 2" (51mm) | 25.0 MPa / 3,625 psi | 10,000 |

4sh hoses work with many hydraulic fittings, such as DKM, DKL, DKOL, DKS, DKOS, DKR, DKRO, ORFS, JIC 37°, SFL, and SFS. These pressure ratings make 4sh hoses a top choice for high-pressure applications.

4sh hoses serve in very high-pressure applications. Many industries use 4sh hose for construction, mining, and oil and gas drilling. These hoses move glycol, hydraulic oil, fuel, water, and air. The applications of 4sh hose often involve harsh environments. The multi-layer spiral wire construction gives 4sh hoses excellent chemical and abrasion resistance. Workers rely on 4sh hoses for heavy-duty hydraulic systems that need strong and durable hydraulic hoses.

Tip: When choosing 4sh hoses, always check the pressure ratings and temperature range to match your system’s needs.

The biggest differences between 4sp and 4sh hoses are in how they are built. Both hoses use strong synthetic rubber for the inside and outside. This rubber keeps out oil, weather, and scratches. The main difference is in the steel wire layers inside. A 4sp hose has four spiraled steel wire layers. These layers make the hose strong and let it bend easily. A 4sh hose has four to six spiraled steel wire layers. This makes 4sh hoses even stronger and able to handle more pressure. The thicker wires in 4sh hoses help them last longer in tough places.

| Feature | DIN EN856 4SP | DIN EN856 4SH |

|---|---|---|

| Tube Material | High-quality synthetic rubber | High-quality synthetic rubber |

| Reinforcement | Four spiraled high-tensile steel wire layers | Four to six spiraled high-tensile steel wire layers |

| Cover Material | Abrasion and weather-resistant synthetic rubber | Abrasion and weather-resistant synthetic rubber |

| Temperature Range | -40 °C to +100 °C | -40 °C to +100 °C |

| Pressure Rating | Medium to high pressure (165–450 bar) | Higher pressure (280–430 bar or higher) |

| Construction | Four spiraled steel wire layers | Four to six spiraled steel wire layers for greater robustness |

| Application | Medium to high pressure hydraulic systems | Extremely high-pressure hydraulic systems |

Note: 4sh hoses have extra steel wire layers, so they are best for the hardest jobs with the most pressure.

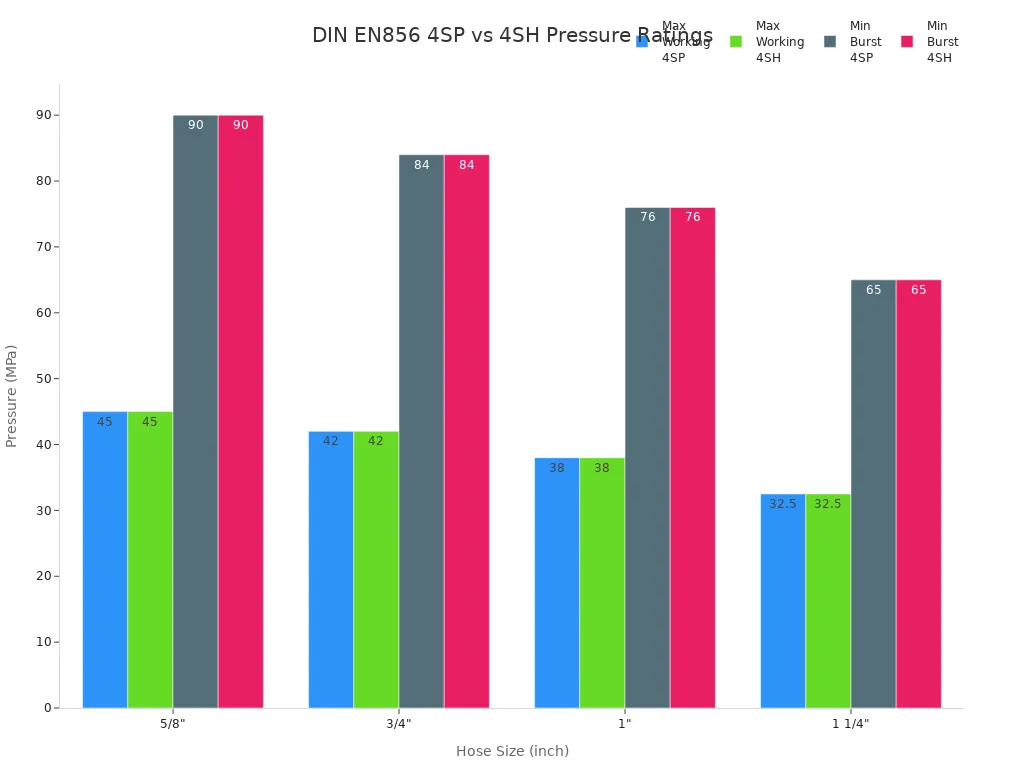

Pressure ratings are another big difference between 4sp and 4sh hoses. Both hoses work in high-pressure jobs, but 4sh hoses can take even more pressure. For example, a 3/4" 4sp hose can handle up to 42 MPa (6,090 psi). A 4sh hose of the same size can handle just as much or even more. The 4sh hose can reach working pressures up to 6,090 psi and burst pressures up to 16,800 psi. This makes 4sh hoses great for the toughest high-pressure jobs.

| Size (inch) | Max Working Pressure 4SP (MPa) | Max Working Pressure 4SH (MPa) | Min Burst Pressure 4SP (MPa) | Min Burst Pressure 4SH (MPa) |

|---|---|---|---|---|

| 5/8" | 45 | 45 | 90 | 90 |

| 3/4" | 42 | 42 | 84 | 84 |

| 1" | 38 | 38 | 76 | 76 |

| 1 1/4" | 32.5 | 32.5 | 65 | 65 |

4sp hoses are good for medium to high pressure jobs.

4sh hoses are best for very high-pressure jobs, like mining and big machines.

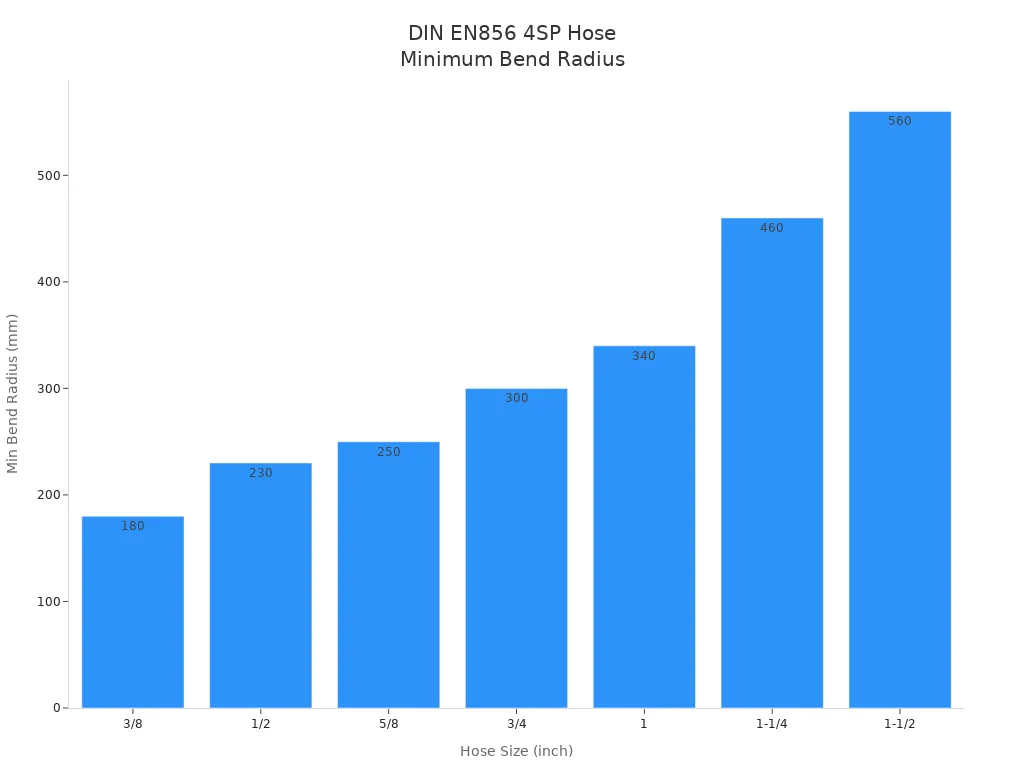

Flexibility and durability are also different for 4sp and 4sh hoses. The 4sp hose bends more easily because it has four wire layers. This helps when you need to fit the hose in tight spots. The smallest bend for a 1" 4sp hose is 340 mm.

| Hose Size (inch) | Minimum Bend Radius 4SP (mm) |

|---|---|

| 3/8 | 180 |

| 1/2 | 230 |

| 5/8 | 250 |

| 3/4 | 300 |

| 1 | 340 |

| 1-1/4 | 460 |

| 1-1/2 | 560 |

4sh hoses have thicker and sometimes more steel wire layers, so they do not bend as much. They need a bigger bend space. But, this makes 4sh hoses last longer and work better in hard places. If you need a hose that bends and takes high pressure, pick 4sp. If you need the strongest hose, pick 4sh.

The outer diameter and size also make a difference between 4sp and 4sh hoses. Both hoses come in sizes from 3/8" to 2". The 4sh hose is usually thicker because of the extra steel wires. This means it needs more space to bend and fit.

| Hose Type | Inside Diameter (in/mm) | Outside Diameter (in/mm) | Size Range (in) | Minimum Bend Radius (in/mm) | Installation Impact |

|---|---|---|---|---|---|

| DIN EN856 4SP/4SH (Example 1) | 0.75 / 19.1 | 1.24 / 31.5 | 3/8" to 2" | 4.7 / 119.4 | Smaller bend radius allows tighter routing and greater flexibility during installation |

| DIN EN856 4SP/4SH (Example 2) | 1.25 / 31.8 | 1.97 / 50 | 3/8" to 2" | 8.2 / 208.3 | Larger diameter requires larger bend radius, affecting installation space and routing |

4sp hoses have inside sizes from about 6.3 mm (1/4 inch) to 51 mm (2 inch). This makes them good for many jobs that need medium to high pressure. 4sh hoses start at 19.1 mm (3/4 inch) and go up to 50.8 mm (2 inch). Their bigger size and higher pressure ratings make them great for big, tough jobs in building, mining, and factories.

Tip: Always look at the outer diameter and bend space before picking a 4sp or 4sh hose. These things matter for how you install and use the hose.

To pick the right hose, you need to know what the job needs. Different machines need hoses that fit their pressure needs. Construction and farm machines often use 4sp hoses. These hoses bend well and work with medium or high pressure. Big machines in mining or drilling use 4sh hoses. These hoses are made for very high pressure and tough jobs.

| Requirement Aspect | DIN EN856 4SP Hose | DIN EN856 4SH Hose |

|---|---|---|

| Reinforcement | Four spiraled high-tensile steel wire layers | Four to six spiraled high-tensile steel wire layers |

| Pressure Range | Medium to high pressure (165 to 450 bar) | Extremely high pressure (280 to 430+ bar) |

| Flexibility | Excellent flexibility for moderate-high pressure | More robust, less flexible |

| Typical Applications | Construction, agriculture, mining, industry | Heavy machinery, mining, drilling, offshore |

| Temperature Range | -40 °C to +100 °C | -40 °C to +100 °C |

| Cost Considerations | Generally less expensive | More expensive due to strength |

| Durability Needs | Moderate to high pressure durability | Extreme pressure and demanding conditions |

Tip: Make sure the hose matches the machine’s pressure needs and where it will be used.

Pressure and the environment matter when picking a hose. Both 4sp and 4sh hoses work from -40°C to +100°C. 4sh hoses have thicker steel wires, so they are better for very high pressure. Always think about the highest pressure, even if it happens fast. The hose must handle this to keep things safe.

Both hoses can resist oil, scratches, and bad weather.

4sp hoses bend more, which helps in small spaces.

4sh hoses are stronger for hard jobs like mining or drilling.

The hose must work with the fluids used, or it can get damaged.

Sun, water, and heat or cold can change how long the hose lasts.

Note: Always check the hose’s pressure rating. Make sure it fits the job’s pressure needs.

Price and how long the hose lasts are important. 4sp hoses cost less for each meter. They still last a long time and fight off scratches and getting old. 4sh hoses cost more because they are stronger and take more pressure. This higher price means they last longer, especially in hard jobs.

| Hose Type | Typical Price Range (USD/meter) | Durability | Best Use Case |

|---|---|---|---|

| 4SP | $0.45 – $2.00 (up to $7.50) | Long service life | Medium to high pressure, flexible |

| 4SH | $0.45 – $1.85 | Extra long service life | Very high pressure, harsh conditions |

Picking the right hose helps stop breakdowns and saves money. It also keeps hydraulic systems safe and working well.

If you swap a DIN EN856 4SP hose for a 4SH hose in a high-pressure system, you could have big problems. Each hose is made for certain pressure levels and places. Using the wrong hose can make the system break or become unsafe.

If you use a 4SP hose instead of a 4SH hose in a high-pressure job, it might leak, burst, or break. The 4SP hose might not handle the higher pressure or tough conditions like the 4SH hose can.

If you go over the pressure limit of a 4SP hose, it can break sooner. This can happen with leaks or even sudden bursts.

If you install the hose wrong, like bending it too much or putting it together badly, it can get damaged.

Things like pulling, rubbing, heat, or using the wrong fluid can also make the hose weaker and not last as long.

If you use a hose that is not strong enough for hard places, it will wear out faster.

Checking hoses often, putting them in the right way, and picking the right hose for the job help stop these problems.

⚠️ Always make sure the hose’s pressure rating, temperature range, and fluid type match what your system needs. This keeps your equipment safe and working well.

Brands like Grandflex and others give clear advice about picking hoses. They make each hose for certain jobs and pressure levels. The table below shows the main differences and tips:

| Feature | DIN EN856 4SP Hose | DIN EN856 4SH Hose |

|---|---|---|

| Reinforcement | Four spirally wound steel wire layers | Four to six layers of spirally wound high-tensile steel wire |

| Pressure Rating | Moderate to high pressure (approx. 165-450 bar) | Extremely high pressure (approx. 280-430 bar) |

| Flexibility | Good flexibility | Less flexible due to extra reinforcement |

| Typical Applications | Construction, mining, agriculture, general hydraulic systems | Heavy-duty construction, mining, offshore drilling, extreme pressure systems |

| Manufacturer Recommendation | Use as specified for application; not generally interchangeable without considering pressure and flexibility requirements | Use as specified for application; recommended for highest pressure needs, not a direct substitute for 4SP |

Manufacturers say you should always look at the product details and rules before swapping hoses. They want you to pick the hose based on how much pressure and what kind of job you have. Using the hose the maker says to use keeps things safe and working their best.

✅ For the best results, follow what the manufacturer says and never swap hoses without checking all the details. This keeps both your equipment and workers safe.

Choosing between DIN EN856 4SP and 4SH hoses depends on what pressure you need, how tough the hose should be, and how much money you want to spend. The table below shows the main differences:

| Feature | DIN EN856 4SP | DIN EN856 4SH |

|---|---|---|

| Construction | Four spiral steel wire layers | Four to six spiral steel wire layers |

| Working Pressure | Up to 450 bar | Up to 500 bar or more |

| Applications | High-pressure equipment | Ultra-high-pressure, extreme use |

| Cost | Lower | Higher |

Grandflex makes a strong 4SP hose for hard jobs. Before you buy, check what the manufacturer says. You should also look at answers to common questions about making changes, shipping, and warranty. This helps you pick the best hose for your needs.

DIN EN856 4SP hoses have four spiral steel wire layers. These layers help them handle high pressure. DIN EN856 4SH hoses use thicker or more wire layers. This makes them even stronger and able to take more pressure. 4SH hoses are best for the hardest jobs.

Grandflex 4SP hoses work from -40°C to +125°C. This means they can be used in very cold or hot places. The hose stays strong and flexible in this whole range.

Both 4SP and 4SH hoses work with most petroleum-based hydraulic fluids. You should always check if the hose matches your fluid before using it. This helps stop damage and keeps things safe.

Experts say you should check hydraulic hoses often for wear, leaks, or damage. You should look at them before each use in important systems. Finding problems early stops failures and saves money.

It is not safe to use a 4SP hose instead of a 4SH hose in high-pressure systems. 4SH hoses can take more pressure. Always follow what the manufacturer says to keep your system safe.