Views: 0 Author: Site Editor Publish Time: 2025-10-22 Origin: Site

Choosing the right sandblast hose is crucial for efficient and safe sandblasting operations. Did you know that an improperly sized hose can drastically reduce your blasting efficiency? This blog will guide you through the factors to consider when selecting the correct sandblast hose size.In this article, you’ll learn how hose size impacts blasting efficiency, safety, and equipment longevity. We will help you avoid common mistakes and optimize your sandblasting operations.

Choosing the correct sandblast hose size is fundamental for achieving the best blasting results. If the hose is too small or too large, it can lead to a variety of problems that impact both performance and safety.

The size of the hose directly impacts the efficiency of the sandblasting operation. A hose that is too small restricts airflow, which in turn reduces the speed at which abrasives travel to the surface. This can cause inconsistent blasting results and lower productivity. When a hose is too small, it increases the resistance, which leads to a drop in pressure at the nozzle. This reduces the abrasives' speed, which is crucial for achieving the desired finish.Conversely, a hose that is too large may lead to air wastage, causing unnecessary pressure drops at the nozzle. While larger hoses can carry more air, they may cause air pressure to decrease too much by the time the abrasive reaches the surface. Therefore, balancing hose size with the blasting requirements is vital for maximizing productivity and achieving consistent, high-quality results.

Improper hose sizing often results in a pressure drop, which can affect blasting quality. For instance, if the hose is too small, the air pressure at the nozzle will be insufficient, leading to slower abrasive delivery and decreased performance. The result is a longer surface preparation process, which ultimately affects the overall time and cost of the operation.Ensuring the hose size is properly matched with the nozzle size helps maintain consistent pressure throughout the blasting process. Pressure loss can also be caused by the length of the hose and other components in the system. It is crucial to select a hose that matches the requirements of your system to ensure that the desired pressure reaches the nozzle, keeping blasting operations efficient.

A hose that cannot withstand the pressure required for blasting operations poses a significant safety risk. Over time, high pressure can cause weak hoses to rupture or crack. Regularly inspecting hoses and selecting the right size can reduce the risk of such failures and increase the safety of the operation.If the hose is too small or does not meet the pressure specifications, it could result in the hose bursting or cracking during operation. This is a safety hazard that can lead to significant injuries or damage to the surrounding environment and equipment. It is crucial to regularly inspect hoses, especially in high-pressure environments, to ensure they are in optimal condition.

● Smaller hoses for increased speed: Many believe smaller hoses make blasting faster, but this leads to pressure drops, reducing blasting efficiency. Smaller hoses actually restrict the flow of abrasives and air, causing an inefficient blasting operation.

● Bigger is always better: While larger hoses may seem like a better option, they can lead to unnecessary pressure loss and air wastage. In some situations, a larger hose might cause more friction, which ultimately affects blasting efficiency.

Choosing the right sandblast hose size requires understanding several key factors that affect both performance and safety. These factors are essential to ensure the efficiency and durability of the sandblasting operation.

The internal diameter (ID) of the hose plays a crucial role in the efficiency of the sandblasting operation. A larger ID reduces friction and pressure loss, allowing more air and abrasive to flow freely to the nozzle. Generally, the hose diameter should be 3-4 times larger than the nozzle's internal diameter to ensure the system works at full capacity.For standard nozzles, a 3/8” ID hose is commonly used. For larger nozzles, hoses with 1” or larger IDs may be needed. Choosing the right ID ensures that the air and abrasive flow efficiently to the nozzle, which is essential for maximizing blasting efficiency and achieving the desired finish.

Hose length directly affects the pressure at the nozzle. Longer hoses create more resistance, which results in pressure loss. It's crucial to select a hose that is long enough to reach the blasting area, but not excessively long, which can lead to inefficient pressure at the nozzle.For every additional 50 feet of hose, expect a slight decrease in pressure. If your operation requires a longer hose, consider opting for a larger diameter to minimize pressure loss. A well-sized hose ensures that pressure is maintained effectively, leading to better blasting performance even in long-range applications.

Ensuring the hose size matches the nozzle size is vital for maintaining optimal performance. If the hose is too small compared to the nozzle, it can restrict the airflow, leading to pressure drops. On the other hand, if the hose is too large, it can result in wasted air, making the system less efficient.Typically, the hose should have an internal diameter that is 3-4 times the size of the nozzle opening. This helps maintain consistent air pressure and minimizes unnecessary pressure loss. Ensuring compatibility between the nozzle and the hose will lead to more efficient blasting.

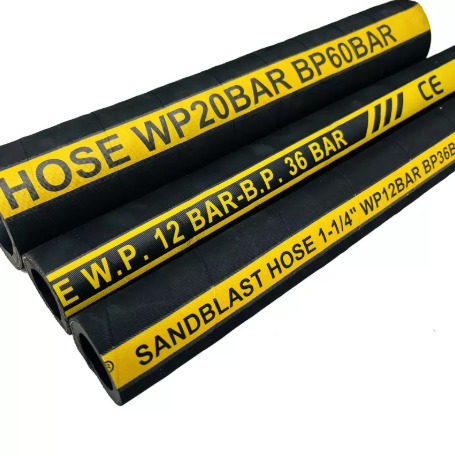

Reinforced hoses provide additional durability and resistance to abrasion, ensuring the hose can withstand harsh conditions. The number of reinforcement layers also plays a critical role in determining the hose’s ability to handle high-pressure applications.

Light-duty sandblast hoses are often used in less demanding applications, such as small-scale or surface cleaning tasks. They are typically reinforced with 2-ply materials and are sufficient for tasks where pressure and abrasives aren’t as extreme. These hoses are suitable for general industrial applications where the intensity of use is moderate.Heavy-duty hoses, on the other hand, are required for high-intensity operations such as mining, construction, or heavy industrial cleaning. These hoses often feature 4-ply reinforcement for enhanced durability. When working with aggressive abrasives or in harsh environments, heavy-duty hoses ensure that the blasting process remains safe and efficient.

Feature | Light-Duty Sandblast Hose | Heavy-Duty Sandblast Hose |

Ply Layers | 2-ply | 4-ply |

Common Materials | Nylon, Polyester | Steel Wire, Nylon, Polyester |

Suitable Applications | Small-scale, surface cleaning | Heavy industrial cleaning, mining |

Durability | Moderate | High |

Cost | Lower | Higher |

The material used for reinforcement affects the overall strength and performance of the sandblast hose. Common reinforcement materials include:

● Nylon: Offers high abrasion resistance and flexibility.

● Polyester: Known for its strength and durability in harsh conditions.

● Steel Wire: Used for extreme pressure applications, providing strength and resistance to wear.

Choosing the right reinforcement material ensures that the hose can handle the specific demands of your sandblasting tasks. For demanding environments, steel wire reinforcement may be necessary, while lighter materials like nylon are suitable for more moderate conditions.

A commonly used rule of thumb for sizing blast hoses is:

● Blast Hose = 3x Nozzle Size (ID)

This means the internal diameter of the hose should be three times larger than the nozzle’s orifice size. While this rule is a good starting point, adjustments may be necessary depending on the specific conditions of your sandblasting setup.

For example:

● Nozzle size: 1/4" → Blast hose size: 3/4"

● Nozzle size: 1/2" → Blast hose size: 1-1/2"

While the 3x rule helps minimize pressure loss, it’s important to consider longer hose runs or more demanding conditions, in which case larger hoses might be required. Using a larger hose will ensure that the pressure loss over the length of the hose is minimized.

Selecting the wrong hose size can lead to several operational problems that can significantly affect productivity and safety.

Using the wrong hose size causes reduced airflow, which slows down the blasting process. This can result in uneven surface finishes and a longer time spent on tasks that should be completed more efficiently. A hose that’s too small leads to friction, which slows down abrasive delivery and reduces the overall efficiency of the sandblasting process.

Incorrect hose sizing puts additional strain on equipment, leading to faster wear and more frequent replacements. Over time, this can become a costly issue for businesses that rely on sandblasting for heavy-duty work. The extra pressure and friction can cause hoses to degrade quickly, leading to increased maintenance costs and more frequent replacements.

A hose that isn’t rated for the required pressure can rupture, posing a serious safety risk to operators. Regularly checking hose sizes and pressure ratings can help prevent accidents and ensure the safety of all workers involved in the sandblasting process. Hose failures can result in dangerous flying debris and high-pressure air being released suddenly, causing injuries or even fatalities.

To avoid mistakes in hose sizing, follow these steps:

1. Assess your nozzle size: Determine the nozzle size you plan to use for the operation.

2. Check hose diameter: Ensure the hose ID is three to four times larger than the nozzle’s ID.

3. Consider hose length: Account for the total hose length and its effect on pressure loss.

4. Select appropriate reinforcement: Choose a hose with adequate reinforcement layers based on the intensity of your application.

Selecting the right sandblast hose size is crucial for both safety and efficiency. The hose size directly impacts pressure, performance, and overall safety during sandblasting. Understanding key factors such as internal diameter, hose length, and nozzle compatibility ensures smooth and effective operations.Proper hose selection reduces downtime, boosts productivity, and minimizes safety risks. Don’t compromise on quality—choose the right sandblast hose for your needs.

For reliable and high-performance sandblast hoses, Qingdao Grantseed Rubber Co., Ltd provides top-notch solutions that enhance your operational efficiency. Their products are designed to meet rigorous industry standards, offering exceptional durability and reliability. Trust in Qingdao Grantseed Rubber Co., Ltd for all your sandblasting needs.

A: Choose a hose with 3-4 times the nozzle size for optimal performance.

A: Longer hoses cause pressure loss. Consider a larger diameter for longer hoses.

A: Proper sizing ensures optimal airflow and consistent pressure at the nozzle.

A: No, smaller hoses restrict airflow, reducing efficiency and performance.

A: Nylon or steel wire reinforcement offers durability, depending on conditions.